Most ordering workflows don’t fail overnight.

They break quietly, under the surface — as volumes increase, SKUs multiply, and teams stretch to keep up. What once felt “good enough” slowly turns into daily friction, hidden errors, and operational stress.

The problem?

By the time most distributors feel the pain, they’re already reacting instead of planning.

In this article, we’ll break down five early warning signs that your ordering workflow won’t scale — even if it’s working fine today — and what these signals typically mean for growing food and goods distributors.

This isn’t sales material. It’s an operational self-check many teams use internally as they prepare for growth.

Warning Sign #1: Orders Depend on Specific People

“Only Sarah knows how this actually works.”

What it looks like

- Orders are handled manually by one or two key people

- If someone is sick or on leave, things slow down

- Knowledge lives in inboxes, spreadsheets, or people’s heads

- New hires take weeks to “learn the ropes”

Why this doesn’t scale

People-based workflows don’t compound. Volume grows, but capacity doesn’t.

As order complexity increases, dependency risk increases with it. The system isn’t resilient — it’s fragile.

Early consequence

- Small mistakes go unnoticed

- Firefighting becomes normal

- Leaders stay too close to day-to-day ops

Long-term cost

Burnout, bottlenecks, and operational risk that limits growth decisions.

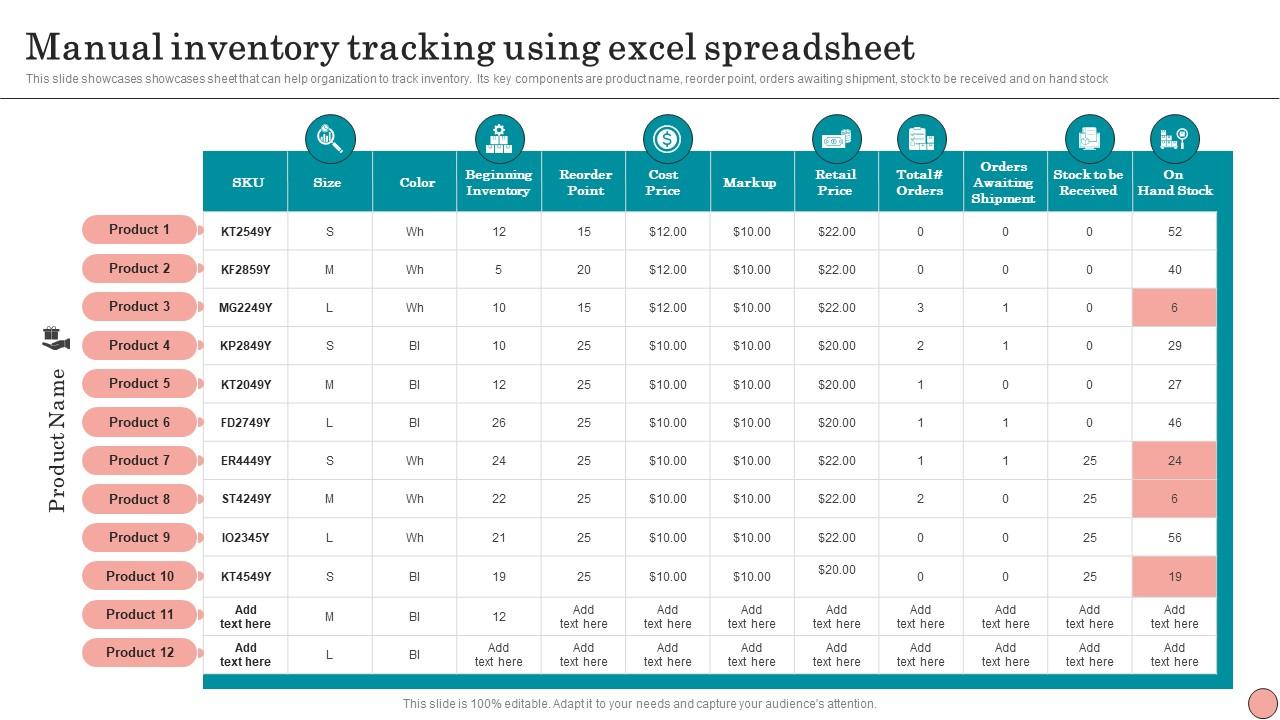

Warning Sign #2: Your Catalogue Lives in Multiple Places

“Just check the latest version.”

What it looks like

- Product lists in spreadsheets, PDFs, emails, and systems

- Pricing updates handled manually

- Availability changes communicated ad hoc

- Buyers and staff see different “versions” of the catalogue

Why this doesn’t scale

Fragmented catalogues create decision lag and error drift.

As SKUs grow, the effort to maintain accuracy grows faster than the business itself.

Early consequence

- Incorrect pricing or unavailable items ordered

- More back-and-forth with buyers

- Increased admin time per order

Long-term cost

Loss of trust, margin leakage, and fulfilment inefficiencies that quietly erode profitability.

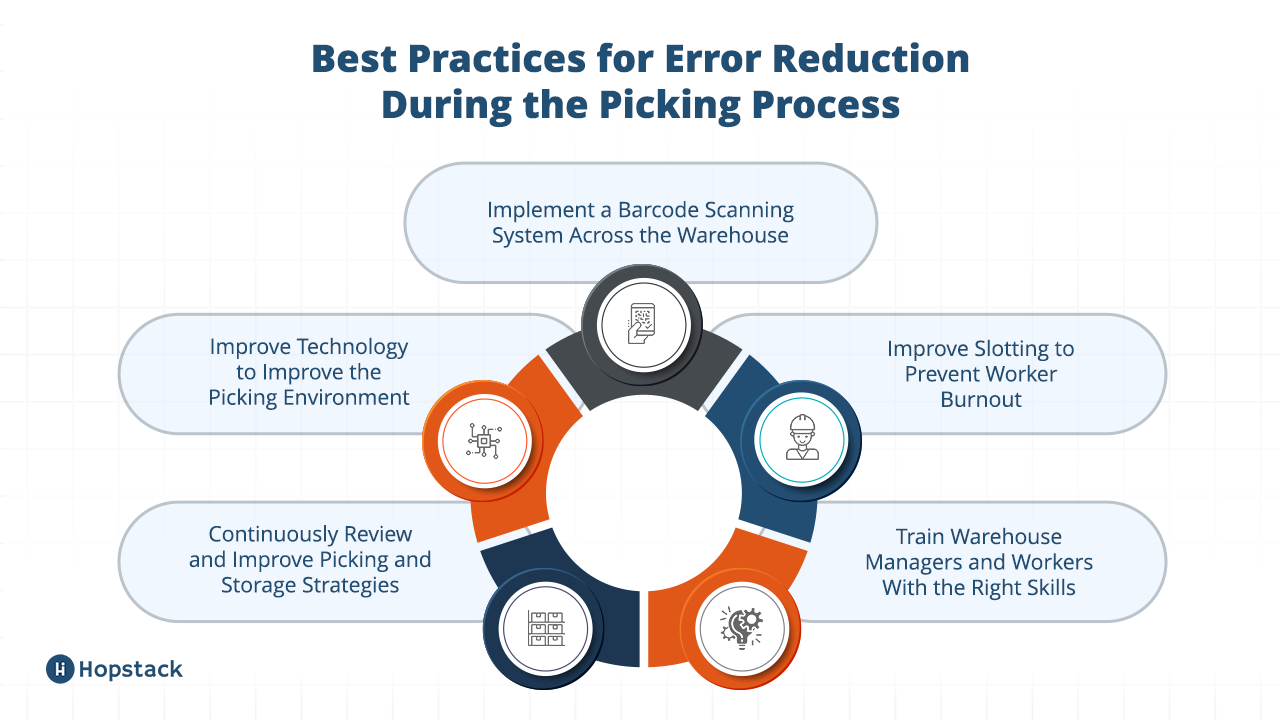

Warning Sign #3: Order Accuracy Declines as Volume Increases

“It didn’t use to be this messy.”

What it looks like

- More frequent picking or packing errors

- Orders need manual checking

- Corrections handled via phone or email

- Issues explained away as “growing pains”

Why this doesn’t scale

Errors don’t grow linearly — they compound.

Each additional SKU, supplier, or buyer increases complexity. Without structural controls, accuracy declines even if effort increases.

Early consequence

- Increased returns or credits

- Strained customer relationships

- Team frustration

Long-term cost

Hidden churn. Buyers may not complain — they just reorder less.

Warning Sign #4: Reporting Is Manual or Retrospective

“We’ll pull the numbers at month-end.”

What it looks like

- Reports built manually in spreadsheets

- Limited real-time visibility

- Data pulled after issues occur

- Leadership decisions made on lagging indicators

Why this doesn’t scale

When insight lags behind reality, decisions become reactive instead of strategic.

You can’t fix what you can’t see — and you definitely can’t optimise it.

Early consequence

- Surprises at month-end

- Difficulty forecasting growth

- Guesswork replaces clarity

Long-term cost

Missed opportunities, inefficient capital allocation, and stalled scaling.

Warning Sign #5: Growth Increases Stress, Not Confidence

“We’re busier, but it feels harder.”

What it looks like

- More orders, but more chaos

- Teams working longer hours

- Leaders hesitate to take on new customers

- Growth feels risky instead of exciting

Why this doesn’t scale

Healthy systems create leverage.

Unhealthy ones create drag.

If growth increases stress, the workflow is already operating beyond its design limits.

Early consequence

- Slower response times

- Morale issues

- Growth hesitation

Long-term cost

Self-imposed growth ceilings and operational stagnation.

What These Signs Are Really Telling You

Individually, these issues seem manageable.

Together, they point to a deeper problem:

Your ordering workflow was built for yesterday’s scale.

The good news?

These signs show up before major failures — which means teams that notice them early can redesign calmly instead of rebuilding under pressure.

How Growing Teams Respond

High-performing distributors don’t wait for systems to break.

They:

- Reduce dependence on individuals

- Centralise catalogues and ordering logic

- Build workflows that absorb complexity

- Improve visibility before volume spikes

- Treat operations as a strategic asset, not a back-office function

Want a quick internal check?

Many teams use a short internal checklist to spot where ordering friction is creeping in — especially as SKUs and order volumes grow.

If you’d like:

- A simple internal checklist, or

- A quick operational snapshot of your current workflow

You can explore a short resource here:

👉 ROI Calculator

No pressure — it’s designed to be useful whether or not you’re actively changing systems.