Food distribution operations rarely fail overnight.

They degrade quietly.

A few extra emails here.

Manual workarounds there.

One more “temporary” spreadsheet added to the process.

Before long, teams feel constantly busy, order errors creep in, and growth starts creating stress instead of momentum.

This article introduces a simple internal checklist many food distributors use to spot operational friction early — before it becomes expensive, chaotic, or customer-facing.

This isn’t sales material.

It’s a practical diagnostic tool you can run internally in under an hour.

What Is Operational Friction (And Why It’s Hard to See)

Operational friction is the hidden resistance inside your workflows — the extra steps, handoffs, clarifications, and rework that slow everything down.

The challenge?

Friction doesn’t announce itself.

It shows up as:

- Teams feeling “busy but not productive”

- Repeated clarifications around orders

- Minor errors becoming weekly occurrences

- Growth requiring more people than expected

By the time friction is obvious, it’s already costing money.

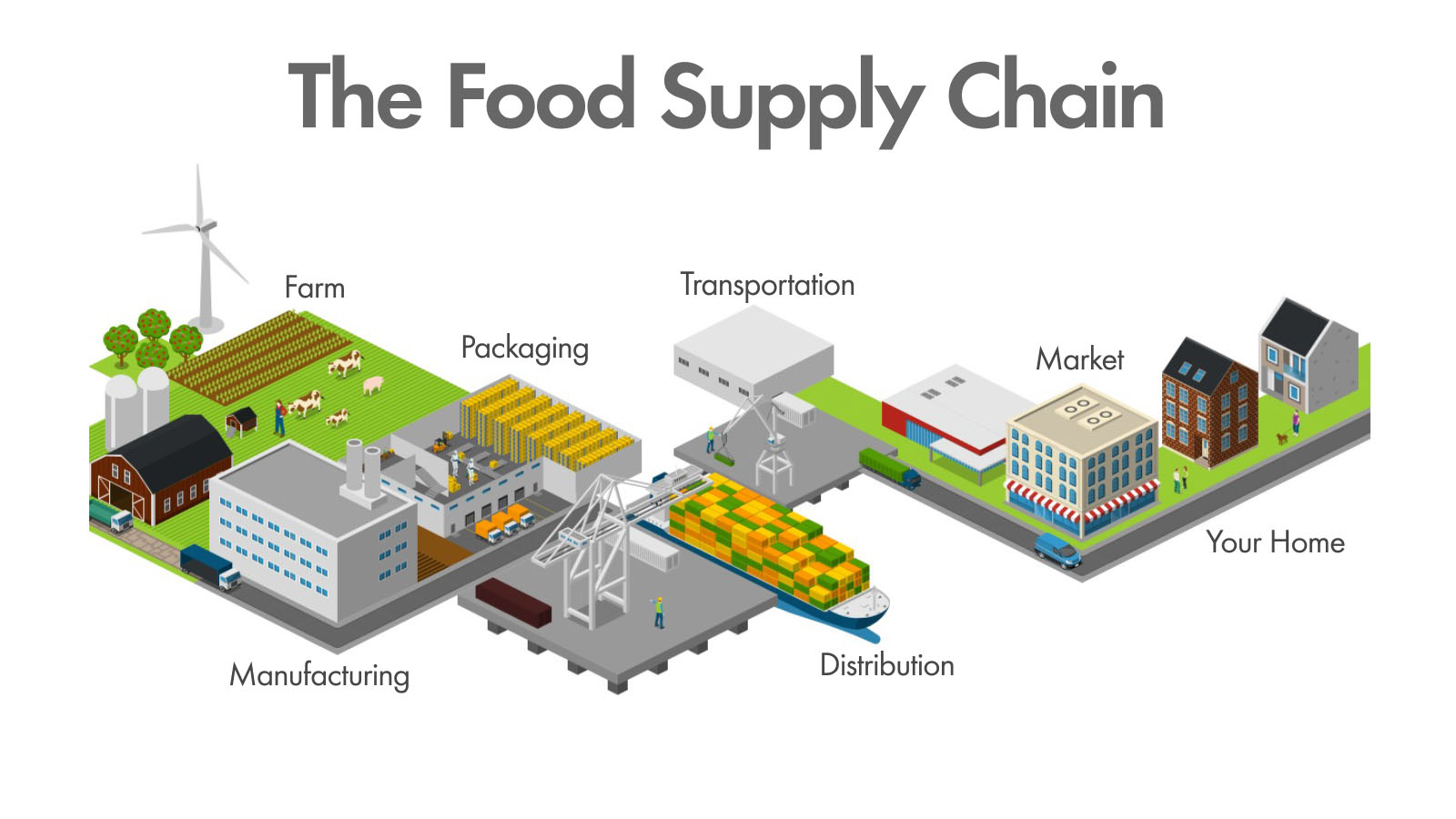

Why Food Distribution Is Especially Prone to Friction

Why Food Distribution Is Especially Prone to Frictionriven traceability.

Food distribution sits at the intersection of complexity and volume.

You’re managing:

- Large, frequently changing catalogues

- Multiple suppliers with different constraints

- Recurring orders with variations

- Tight delivery windows

- Compliance and traceability requirements

Most friction doesn’t come from one big failure — it comes from small mismatches between systems, people, and growth.

How to Use This Checklist

Before diving in, align internally on two rules:

- This is not a performance review

- This is not about blame

The goal is visibility, not perfection.

Have 2–4 people from ops, admin, or customer service answer these questions honestly.

The Internal Checklist

1. Ordering & Intake Friction

Ask Yourself

- Do orders arrive through multiple channels (email, phone, WhatsApp, spreadsheets)?

- Do staff manually re-enter order details into another system?

- Do customers frequently clarify or correct orders after submission?

- Are “special instructions” common and hard to track?

What This Signals

If yes to more than one, your ordering process is absorbing unnecessary cognitive load.

Manual intake doesn’t scale — it just hides inefficiency inside people.

2. Catalogue & Product Management Friction, Not Just Labels

Ask Yourself

- Are price or product updates communicated via email or PDF?

- Do customers reference outdated product lists?

- Are substitutes handled manually each time?

- Do staff “know” what’s available rather than seeing it clearly?

What This Signals

Catalogues that live outside systems become operational debt.

Every manual update increases the chance of:

- Wrong pricing

- Order errors

- Customer frustration

3. Order Accuracy & Rework

Ask Yourself

- How often are orders amended after confirmation?

- Do picking/packing teams flag unclear instructions?

- Are mistakes fixed informally rather than tracked?

- Is “we’ll fix it next time” a common response?

What This Signals

Rework is one of the most expensive forms of friction — and the least visible.

If errors aren’t logged, they’re repeating silently.t they do best: running impactful businesses.

4. Internal Visibility & Status Tracking

Ask Yourself

- Can anyone see order status without asking someone?

- Do updates rely on verbal handovers or messages?

- Are customers asking “where is my order?” regularly?

- Does status tracking differ between teams?

What This Signals

When visibility is missing, communication fills the gap — at a high cost.

More messages ≠ better operations.

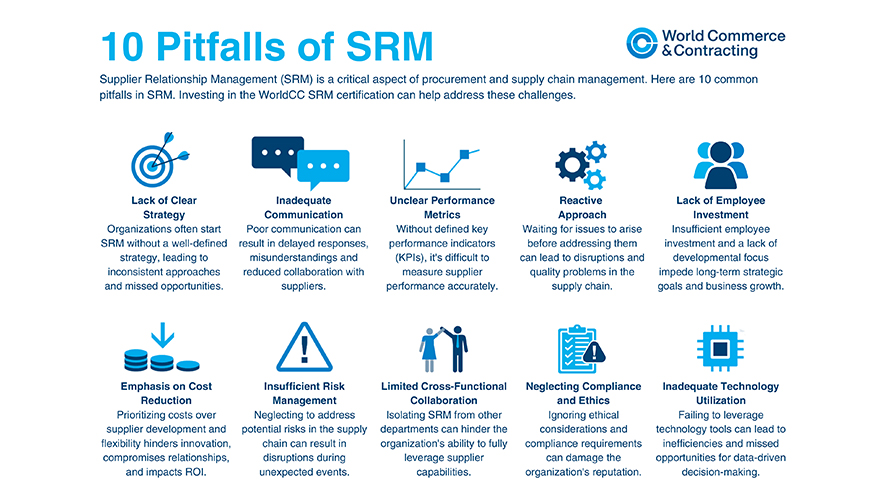

5. Supplier Coordination Friction

Ask Yourself

- Do suppliers send availability updates in different formats?

- Are lead times remembered rather than enforced?

- Are substitutions negotiated order-by-order?

- Does supplier onboarding feel slow or manual?

What This Signals

Supplier inconsistency multiplies internal complexity.

Without standardisation, ops teams become translators instead of operators.

6. Compliance & Documentation Load

Ask Yourself

- Are certifications stored across folders, emails, or drives?

- Is compliance checked reactively instead of continuously?

- Do customers request proof repeatedly?

- Is documentation reviewed manually each time?

What This Signals

Compliance friction is dangerous because it feels administrative — until it becomes urgent.

Reactive compliance always costs more.

7. Growth Stress Test

Ask Yourself One Final Question

If order volume doubled in the next 6 months, would this system still work?

If the honest answer is “only with more people,” friction is already embedded.

How to Interpret Your Results

- 0–3 friction points

You’re in a strong position — keep monitoring. - 4–7 friction points

Early-stage strain. This is the best time to act. - 8+ friction points

Growth is being taxed by your systems. The cost is compounding.

The Key Insight Most Teams Miss

Operational friction doesn’t show up on financial statements.

It shows up as:

- Burnout

- Slower onboarding

- Customer complaints

- Margin leakage

The earlier you surface it, the cheaper it is to fix.

What to Do After the Checklist

You don’t need to solve everything at once.

Start by:

- Centralising visibility

- Reducing manual handoffs

- Standardising repeat workflows

Small structural improvements compound fast.

Want to sanity-check your results?

Some teams run this checklist internally, then use a simple snapshot tool to estimate how much time and cost friction is creating as volumes grow.

👉 Run a quick operational snapshot here:

Calculate Return On Investment

Even if now isn’t the right time to change anything, this checklist — and the snapshot — can be useful reference points as complexity increases.